I’ve not posted much on this site in a long time. It’s not that I’ve not been busy, rather, quite the contrary. It seems as though time just continues to accelerate and it gets harder and harder to find the time to document what I’m doing. I’m finding there is great value in this, though, and I plan to do better.

One ham radio ‘adjacent’ activity I’ve found myself exploring of late has been capturing and feeding aviation telemetry. This presently ranges from fairly commonplace data like ADS-B and NOAA balloon sondes to a bit more esoteric stuff like VHF ACARS, L-Band ACARS (decoded from INMARSAT geostationary satellites) and even ACARS over Iridium. I feed my ADS-B data from both 1090 and 978MHz to ADSB.fi and my ACARS data in its various forms and from various sources to Airframes.io. Balloon sonde data at 400MHz is currently fed to SondeHub.

That leads us to the balloons. Lots of balloons. The National Weather Service (NWS) launches balloons with radiosonde payloads twice daily from something like 95 sites. One of those is just West of Omaha NE, placing Central Iowa right in the middle of their landing zone for many flights. There’s a growing community of folks in the area both tracking/feeding the sonde data, but also working to recover them. More on that in another post, most likely. In any case, my good friend Clint (K0GR) and I have undertaken several ‘interesting’ recoveries over the past couple of months, and we both monitor the SondeHub website closely for flights that might make good targets for recovery.

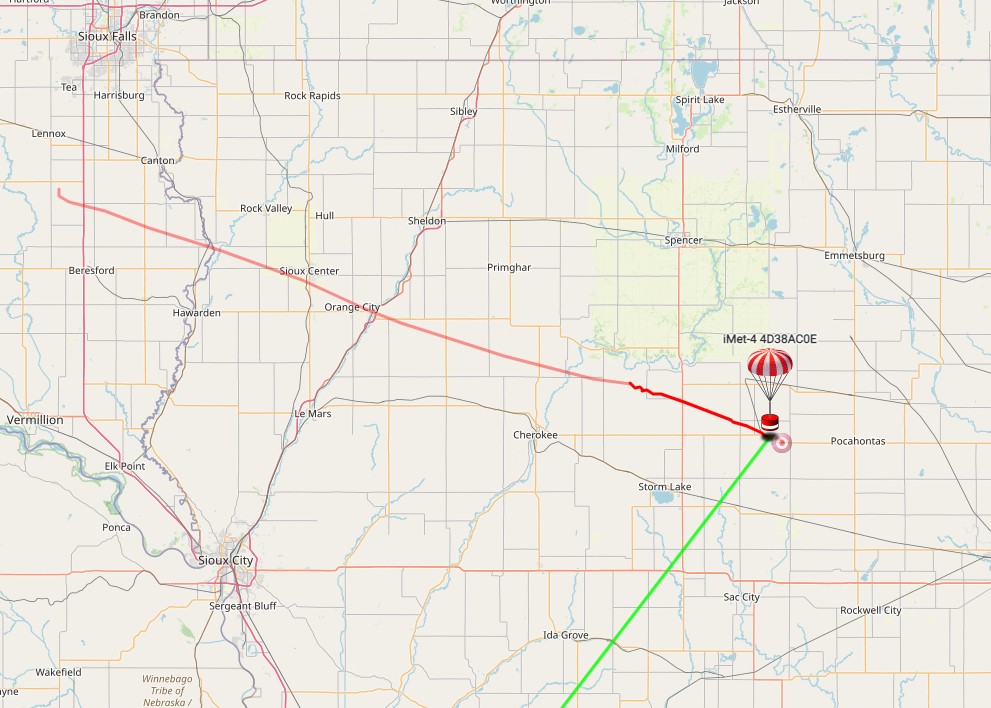

On the morning of 29 March 2023, Clint texted and noted a different sonde had shown up than we were used to. We’re used to the NWS/NOAA flights that currently utilize Graw DFM-17 sondes. This was an InterMet iMet-4 sonde (s/n 4D38AC0E). Curious. I remotely connected to my SondeHub feeder through SSH and confirmed I had very briefly tracked this sonde, and it didn’t appear to be an artifact. The SondeHub track can be viewed here: iMet-4 4D38AC0E

This sonde flight seemed unusual due to the fact the NWS has only been launching Graw DFM-17 sondes in this region, but also because there were no known launch sites correlated with the flight prediction generated by SondeHub. While attempting to determine if the NWS was unexpectedly launching from a new site south of the Sioux Falls SD area, I came across an article from South Dakota Public Broadcasting published in July 2022 that referenced balloon launches in the Sioux Falls area from a private aerospace company: Raven Aerostar. Interesting! https://listen.sdpb.org/science/2022-07-13/sorry-not-an-alien-test-balloons-over-sioux-falls-area-spark-calls-to-weather-service

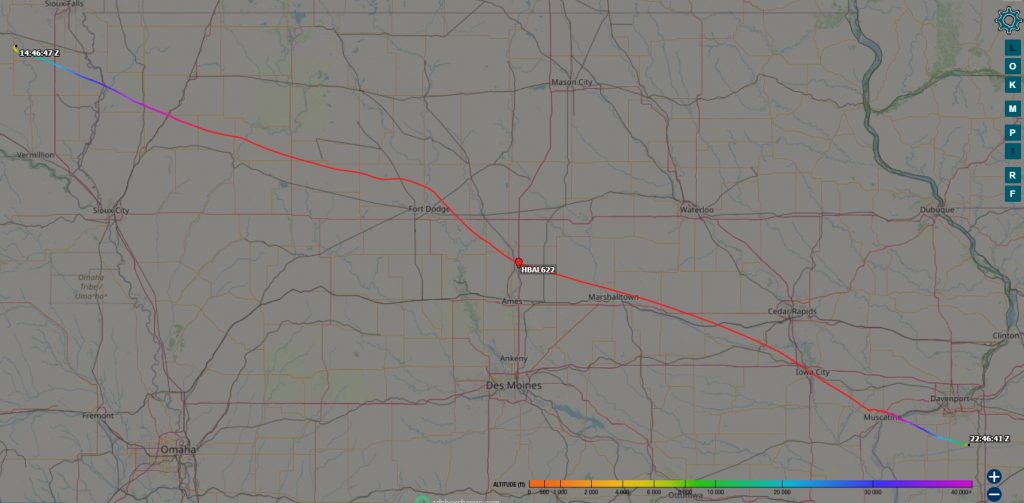

Further exploration led me to find an online project (StratoCat) based in Argentina that is dedicated to cataloging stratospheric balloon flights. https://stratocat.com.ar/stratocate.htm The StratoCat site had tracking data for some recent flights from Raven Aerostar utilizing ADS-B data, including a very recent flight that launched from a brand-new location near Hurley SD – just south of Sioux Falls. Speculating that we might be looking at a sounding flight prior to launch of another stratospheric flight, I pulled up the ADS-B map, and sure enough… just two minutes before the last telemetry was received from the iMet-4 sonde (14:48:06Z), ADS-B telemetry was picked up (14:46:47Z) for a new flight that identified itself as HBAL622 (ICAO hex ACEEC8, FAA registration N932TH). The launch appears to have originated from a private grass-strip airfield: Dangel Airport (K2SD7) near Hurley SD, N43.3333167 W97.0628306. Interestingly, Google Maps also now appears to have been updated by someone to show this location as “Aerostar Flight Operations.”

The flight progressed slowly from SE South Dakota and across Iowa reaching altitudes approaching FL680, with my ADS-B feeder providing data for a good portion of the flight. The full flight track can be viewed on the ADSBx website: HBAL622 flight 29MAR2023.

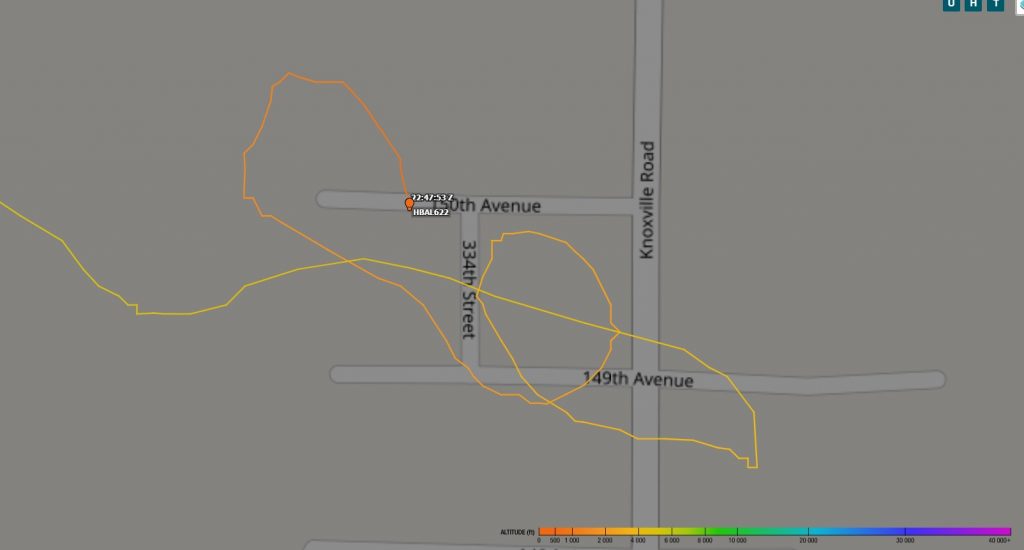

ADS-B tracking on ADSBExchange ceased at approximately 1,650’ AGL, however, ADS-B coverage was maintained through an ADSB.fi feeder until the balloon landed at 22:47:53Z.

Based upon the ADS-B reporting, it appears the landing site was near some homes in Swedona IL, N41.28193 W90.44642.

Hopefully this is the first of many flights from this new launch site.

There are no special skills or tools needed to participate in the workshop, just the ability to follow instructions and an interest to have a good time. Each participant will get a complete kit with all the parts needed to build an antenna with a male BNC connector on the end of the coax. Adapters for your HT or handheld scanner will be available for a small additional fee when registering. We will have all the tools and supplies available so you will leave the workshop with a tested and functioning antenna. During the workshop, we will provide some additional ideas for enhancements to make later if you so choose. If you bring your HT or handheld scanner, there will be a fox hidden outside for you to practice finding.

There are no special skills or tools needed to participate in the workshop, just the ability to follow instructions and an interest to have a good time. Each participant will get a complete kit with all the parts needed to build an antenna with a male BNC connector on the end of the coax. Adapters for your HT or handheld scanner will be available for a small additional fee when registering. We will have all the tools and supplies available so you will leave the workshop with a tested and functioning antenna. During the workshop, we will provide some additional ideas for enhancements to make later if you so choose. If you bring your HT or handheld scanner, there will be a fox hidden outside for you to practice finding.